IKO’s Advanced Solutions Produce Durable & Dependable Cam Followers

Cam followers are a great way to convert rotary motion to linear motion. But as with any motion product used in automated systems or heavy-duty production machinery, failure is not an option. To maximize the uptime of your motion system, it’s important to keep two common causes of bearing downtime in mind: misalignment and inadequate lubrication.

Here’s how these conditions can bring your bearings to a halt:

• Misalignment. When a bearing is mounted improperly, misalignment creates impact loads that produce wear and friction between the bearing’s outer ring and side plate that can lead to a breakdown.

• Inadequate lubrication. While oils and greases go a long way toward protecting rolling contact surfaces, removing a cam follower from a machine or accessing a hard-to-reach area for relubrication can be expensive and time-consuming. These factors can defer maintenance and create unnecessary risk of failure.

These challenges can be avoided with the right cam follower.

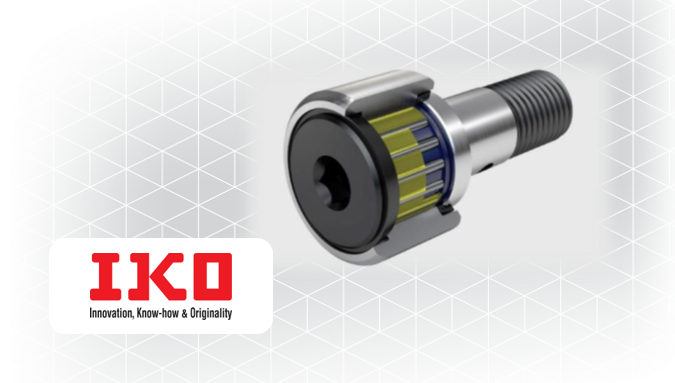

The IKO CR…BSE cam follower, part of the Inch Series, is designed to solve common causes of bearing failure and ensure a long operating lifetime. They deliver reliable performance thanks to two IKO innovations:

• A ThrustDisk™ seal. This special seal slides into the outer ring’s contact areas and handles axial loads caused by misalignment. It also resists heat and contamination to improve bearing longevity.

• C-Lube. CR…BSE bearings are lubricated with a thermosetting solid-type lubricant that fills the inner space of the bearing. This lubricant helps provide long-term, maintenance-free operation by eliminating routine re-lubrication maintenance and improving performance reliability.

Since ThrustDisk seals address axial loads caused by improper mounting, these cam followers can accommodate higher loads. The combination of ThrustDisk technology along with C-Lube ensures reliable performance and long life. In addition to its failure-prevention features, the CR…BSE offers a low coefficient of friction, good rotational performance and easy mounting. Stud diameters range from 0.19" to 0.375".

Gain Peace of Mind for Critical Motion Systems

When your demanding industrial application needs a reliable and long-lasting cam follower, you can’t risk failure or downtime due to misalignment or a time-consuming maintenance schedule. It pays to select a cam follower that can receive axial loads, keep contaminants out and prevent heat from damaging the unit — all while taking the guesswork out of maintenance.

DISCLAIMER: The above content is provided by the supplier. Applied does not guarantee the accuracy or timeliness of the content.

The above content is provided “AS IS”, AND ANY AND ALL EXPRESS AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS ARE HEREBY EXCLUDED.

All warranties, if any, are solely from the supplier.

Find a Service Center

Find a Service Center